In modern manufacturing, materials are the foundation of reliability, durability, and design efficiency. Across sectors—construction, automotive, industrial fabrication, and consumer products—engineers face constant pressure to balance cost, strength, weight, and sustainability. The choice of metal can influence performance outcomes more than any tool or technique used afterward. Whether you’re building structural frameworks or designing precision components, understanding material behaviour is essential for making informed decisions that drive long-term success.

The metal industry has evolved rapidly, driven by global supply chains, emerging production technologies, and industrial sustainability targets. Manufacturers are no longer satisfied with simply assembling strong parts—they must now prioritise lifecycle performance, environmental impact, and cost effectiveness. This shift places steel, aluminium, and other alloys in the spotlight as industries seek materials that can deliver value over time. The goal is clear: select the right metal for the right application to reduce failures, extend usage cycles, and create components that stand up to real-world stress.

Strength and Durability: The Core of Industrial Fabrication

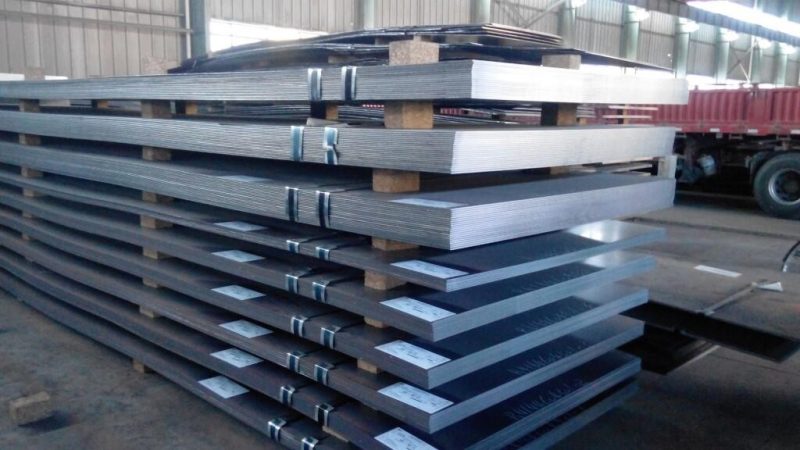

Among all materials used in fabrication, metals remain dominant due to their ability to withstand load, impact, temperature shifts, and environmental exposure. Steel, for example, is known for its impressive tensile strength and resistance to deformation. It is widely used in construction beams, factory equipment, heavy-gauge piping, and structural reinforcements. When formed or welded correctly, steel offers exceptional longevity even in demanding industrial environments.

Aluminium, on the other hand, is lightweight and corrosion-resistant, making it ideal for aerospace, transport, and applications where weight reduction improves efficiency. But unlike steel, it may require additional treatment or reinforcement when used in high-stress environments. This is where composition, thickness, and material grade play an important role—decisions that influence cost, safety, and maintenance requirements.

Long-term durability matters not only for product integrity but also for financial efficiency. A well-selected material reduces repair cycles, protects against catastrophic failure, and ensures that production output remains stable. In business terms, better material selection is not just engineering—it is smart investment.

The Role of Steel in Precision Components

Steel continues to lead global metal consumption due to its exceptional balance of affordability, formability, and strength. It can be machined, welded, bent, or rolled into shapes suitable for architecture, industrial machinery, vehicle chassis, agricultural equipment, shelving structures, and countless other applications. The consistency and predictable performance of steel helps manufacturers maintain tolerances while streamlining fabrication workflows.

One application example lies in tubular metal. A round steel tube offers strong load-bearing capacity, smooth aesthetics for visible structures, and excellent performance under rotational or compression forces. It can be used in fencing systems, fabrication frameworks, automotive roll cages, and manufacturing machinery—proving how versatile steel remains in modern engineering.

Performance and Sustainability in Today’s Market

Sustainability is no longer optional. Increasing environmental regulation means manufacturers must rethink sourcing, recycling, and material waste. Steel, being one of the most recycled materials globally, has strong advantages in circular economy models. Scrap steel can be melted and repurposed repeatedly without losing structural integrity, which supports carbon-reduction objectives across the industrial chain.

In addition, developing alloys and coatings reduce corrosion, extend outdoor performance, and minimise lifetime maintenance. Protective galvanising, powder coatings, and treatment processes can significantly enhance resistance to chemicals, salt environments, and weather. For companies aiming to optimise product lifespan while aligning with sustainability goals, steel-based components often offer a reliable, long-term solution.

Recent years have also seen a push for smarter manufacturing using automation, AI-driven inspection systems, and precision cutting tools. These developments help manufacturers reduce waste, optimise cutting patterns, and improve safety. By combining high-performing metals with advanced fabrication technology, industries are producing stronger, more efficient products faster than ever before.

Choosing the Right Material for Your Project

Every project requires a tailored approach. Consider the following key factors when selecting metal for fabrication:

- Load capacity & strength requirements

High-tension frameworks require materials that resist bending and fatigue. - Weight and transportation considerations

Lighter materials improve mobility and efficiency in automotive and aerospace projects. - Environmental exposure

Moisture, chemicals, and heat influence metal selection and protective coating needs. - Machinability and forming limitations

Production cost and lead time depend on ease of cutting, bending, or welding. - Aesthetic value

Visible installations often require a polished or coated finish. - Lifecycle cost vs upfront cost

The most economical material is often the one that lasts the longest—not the cheapest.

Selecting the right metal is an investment in performance, safety, and reputation. The industries that thrive are those that view material choice not as a commodity decision, but as a core strategic component of product development.

Conclusion

Strong manufacturing doesn’t begin with assembly—it begins with selecting materials capable of meeting design demands over time. Metals like steel remain essential in an expanding industrial landscape where reliability, efficiency, and sustainability matter more than ever. By understanding the strengths and limitations of different metals, businesses can deliver products with measurable performance benefits and long-term value.

Material choice is the foundation of great engineering. When durability is required, precision matters—and the right metal makes all the difference.